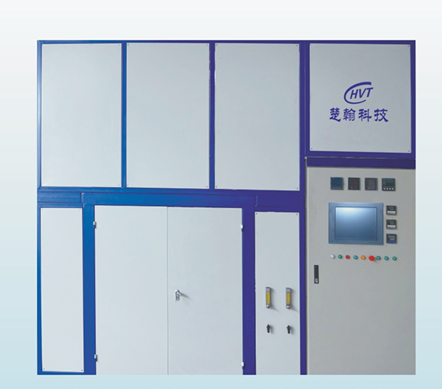

small vacuum heat treat furnace

A small vacuum heat treat furnace is an advanced thermal processing system designed for precise heat treatment of materials in a controlled, vacuum environment. This specialized equipment operates by removing air and other gases from the heating chamber, creating an oxygen-free atmosphere that prevents oxidation and contamination during the heating process. These furnaces typically operate at temperatures ranging from 1000°F to 2400°F (538°C to 1316°C) and are equipped with sophisticated temperature control systems for maintaining precise thermal conditions. The vacuum environment ensures superior surface finish quality and eliminates the need for protective atmospheres or quench oils. These furnaces are particularly valuable in industries requiring high-precision heat treatment of small components, such as aerospace parts, medical devices, and specialty tools. The system includes advanced features such as programmable temperature profiles, rapid cooling capabilities, and automated process control. Modern small vacuum heat treat furnaces often incorporate digital interfaces for easy operation and monitoring, allowing users to track and adjust parameters in real-time. The compact design makes them ideal for research laboratories, small manufacturing facilities, and specialized heat treatment operations where space is at a premium.